Design and Engineering

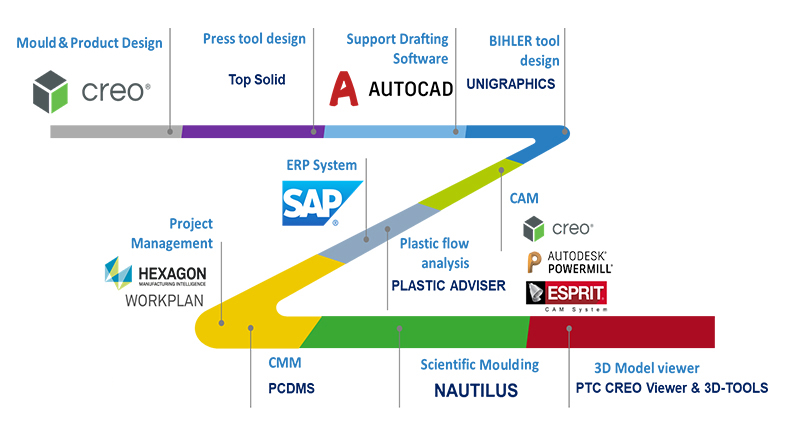

Everything begins at the design stage with a concept then DFM and Mould flow analysis, afterwards design and design reviews, till the release of the final design.

Throughout those steps, we ensure an optimal process for designing the Moulds and tools as per the customer requirements in term of size, cycle time and features and eventually ensure providing our customers with a unique tool design and excellent Mould / tool performance on later stage.

Reverse Engineering

alfanar Moulds factory has extended its scope, even to start before moulds design, so we have the capability of starting with product design where we can offer our customers with the possibility of designing their products using a referenced product sample and using our best-in class equipment and software (such as 3D scanners, CMM equipment, etc.), we start the process of product duplication and modeling of the required product (whether it was a component subassembly or finish good) without the aid of drawings or documentation.