Core Capabilities

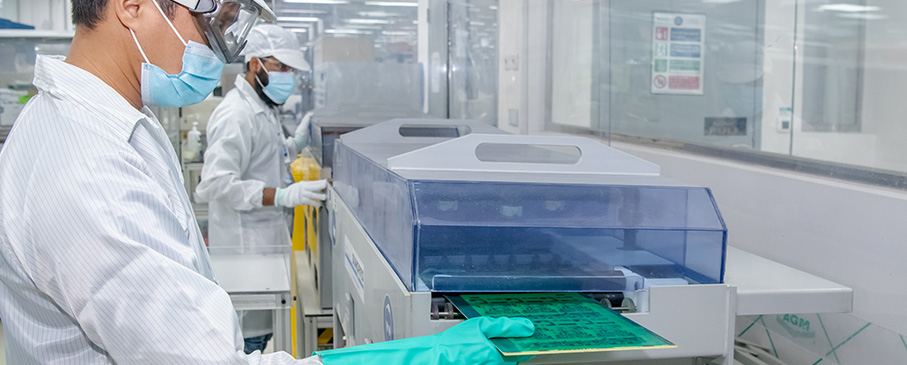

1. Manufacturing Expertise

As a PCBA manufacturer and Electronics Manufacturing Services provider, our expertise in prototyping, tooling, electronic design, and parts assembly is under the direction of professional engineers and technicians.

To develop innovative solutions that add significant value to end products, we offer our customers the appropriate expertise:

- Expert engineers and designers

- High-quality and reliable components

- Lean production

- Conformance to CE, UL, RoHS and other standards

- Environmental Management System ISO14001